Custom Inlay, Hardware & Electronics Upgrades

Precision craftsmanship and musician-first engineering—from aesthetic inlays to noise-free wiring, pickup swaps, and pro electronics.

Upgrade your instrument with confidence

We combine artful detailing with technical rigor: custom fretboard and headstock inlays, premium hardware replacements, shielded wiring and grounding, pickup upgrades, and complete electronics overhauls—all done cleanly, reversibly, and documented for your records.

Custom inlay work

Custom inlays, flush-set and finish-matched

We cut clean pockets, bond with appropriate adhesives, level to radius, and polish to match surrounding finish—no witness lines, no high spots.

- Radius: Matched to board curvature

- Finish: Micro-mesh and compound blend

- Fit: Tight tolerances, clean edges

Design and install bespoke inlays in shell, wood, resin, or composite. We match radius, slot depth, and finish for a seamless look.

- Design: Vector drafts and scale proofs

- Materials: MOP, abalone, ebony, maple, brass

- Finish: Flush set, leveled, polished

Wiring upgrades & grounding

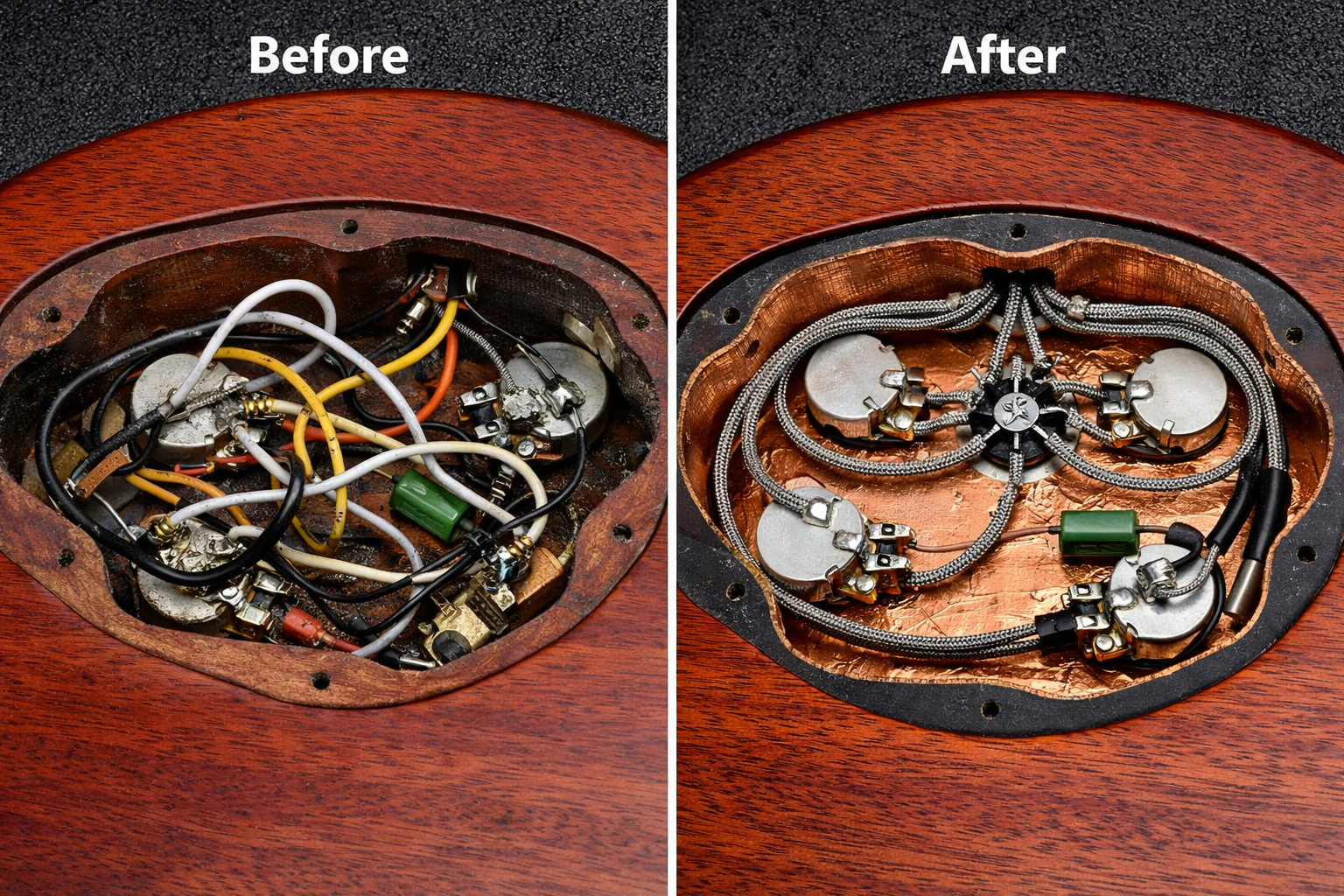

Metal-braid shielded wiring & Common ground topology

We use a central ground node to minimize ground loops. Mechanical ground bonds are tested for continuity and strain relief is applied at stress points. We cover the braiding with insulation for additional protection.

- Continuity: Meter-tested at each junction

- Routing: Clean paths, no pinch points

- Noise: Reduced RF pickup and buzz

Metal-braid shielded harnesses, star-ground topology, and cavity shielding for hum reduction without killing your tone.

- Cable: Braided shield, low-capacitance

- Ground: Star ground, solid mechanical bonds

- Shielding: Copper/graphite cavity treatment

Hardware replacements & upgrades

Hardware Replacement or Upgrades

Swap tuners, bridges, saddles, nuts, knobs, and strap locks with precise fitment and torque specs—no stress, no guesswork.

- Fitment: Drill templates and bushing sizing

- Stability: Proper nut slots and break angle

- Longevity: Anti-corrosion prep and thread care

Pickup upgrades

Pickup Upgrades

P-90, single-coil, humbucker, mini-hum—voicing to match your style with height, tilt, and pole-piece optimization.

- Selection: Magnet type, DC resistance, EQ

- Install: Clean routs, clean solder, clean fit

- Setup: Balanced output across strings

Variety of Upgrade Options.

- Magnets:

- Alnico II

- Alnico III

- Alnico V

- Alnico VIII

- Ceramic

- Rare Earth - Active Pickups

- Grounded / Shielding:

Electronic Component Replacements & Upgrades

Electronics Replacement or Upgrades

CTS/Bourns pots, Switchcraft jacks, quality caps, treble bleed networks, coil-split/series options, and clean control layouts.

- Components: Pro-grade pots, switches, caps

- Layouts: Ergonomic knob and switch positions

- Reliability: Heat management and strain relief

Documentation & Reversibility

Documentation

Every upgrade is photographed and logged with wiring diagrams, component specs, and reversible paths when possible.

- Diagrams: Final harness map with color-coding

- Photos: Before/after and cavity internals

- Notes: Future service references

Precision matters at every step

Upgrade process

Consult & design

We define goals, tone, aesthetics, and constraints. Diagrams and mockups provided for clarity.

Prep & protection

Tape-offs, guards, and fixtures protect the finish and ensure accurate drilling/cutting.

Install & integrate

Hardware seated to spec, wiring soldered cleanly, pickups mounted and aligned.

Test & verify

Continuity, polarity, phase, hum tests, and play checks for feel and response.

Document & deliver

Photos, wiring map, component list, and care notes included in your final packet.

Before & after

Hover or tap to compare—see the clarity, fit, and finish we deliver.

Wiring & shielding

From stock spaghetti to tidy, braided harness with star ground and cavity shielding.

Hardware fitment

Upgraded bridge and tuners, precise alignment, improved sustainability and feel.

Custom inlay

Design to finished piece—flush, leveled, polished, and finish-blended.

FAQs

Can upgrades be reversed?

In most cases, yes. We design wiring and hardware changes with reversible paths. Permanent ops (e.g., routs for larger pickups) are discussed and approved prior to work.

Do you provide parts?

We can source premium parts or install the components you provide, after verifying compatibility and tolerances.

How do you reduce hum?

Braided shielded cable, star-ground topology, cavity shielding, correct polarity/phase, and clean soldering practices.

What's the turnaround?

Most swaps can be completed in a day or two. Custom inlay and complex electronics vary by scope. We’ll confirm timelines during consult.

Ready to elevate your instrument?

Tell us your vision—tone goals, aesthetic preferences, and playing context. We’ll design the upgrade, execute cleanly, and document everything.

Get a custom quote